ANSI Standard Dual Eccentric Butterfly Valves

Product Details:

- Product Type BFV

- Size Drinking water system and other water treatment pipelines

- Structure Butterfly

- Application Drinking water system and other water treatment pipelines

- Sealing RUBBER

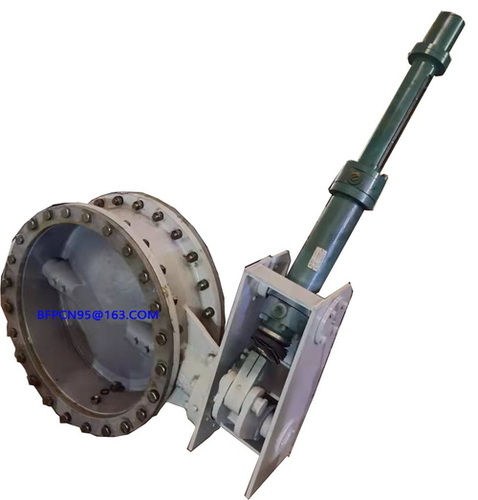

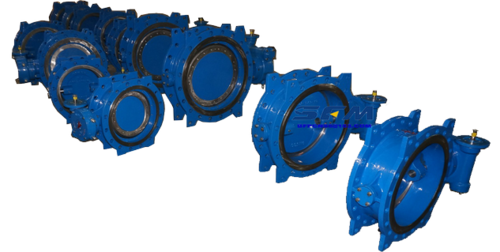

- Type Double flanged dual eccentric

- Power Manual

ANSI Standard Dual Eccentric Butterfly Valves Product Specifications

- Drinking water system and other water treatment pipelines

- Water

- Manual

- RUBBER

- Medium Pressure

- BFV

- Double flanged dual eccentric

- ≤ 80 Celsius (oC)

- Butterfly

- Drinking water system and other water treatment pipelines

ANSI Standard Dual Eccentric Butterfly Valves Trade Information

- SHANGHAI

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 500 Per Month

- 30 Days

- Plywood case suitable for sea transportation

- Western Europe, Australia, North America, Eastern Europe, Africa, Middle East, South America, Asia, Central America

- All India

- TS ECM CE API607 ISO9001 ISO14001 OHSAS18001

Product Description

2. Sealing ring adopts stainless steel, which has the advantages of metal hard seal and elastic seal.It has excellent sealing performance under low temperature and high temperature,corrosion resistance, long service life.

3, Body sealing surface use stainless steel or cemented carbide, which is wear resistance, long service life.

4. Large size butterfly board adopts truss structure of high strength, large flow area and low flow resistance.

5. The valve has bi-direction sealing function. It can be installed in any direction without the limitationof medium flow and space position.

6. The drive device can beinstalled in multiple positions (rotation of 90 or 180 ) for easy use by theuser.

Flanged metal or rubber butterfly valves are widely used in drinking water, thermal pipelines, boiler auxiliary systems, petrochemical and metallurgical industries to cut off and regulate various non-corrosive andcorrosive medium.

The manual butterfly valve is used in dust-bearing cold wind or hot air pipelines of chemical engineering, building materials, power station, glass andother industries as control device toregulate flow rate or cut off gas medium. It is installed in pipelineswith medium temperature 300 and nominal pressure of 0.1-4 Mpa to connect, open orclose or adjust medium. The valve should be generally installed horizontally inthe pipelines.